7t6395 Track Roller: A Step-by-Step Guide

The 7T6395 Track Roller is an essential component for tracked heavy machinery, providing stability and support. This step-by-step guide will cover its installation, maintenance, and troubleshooting.

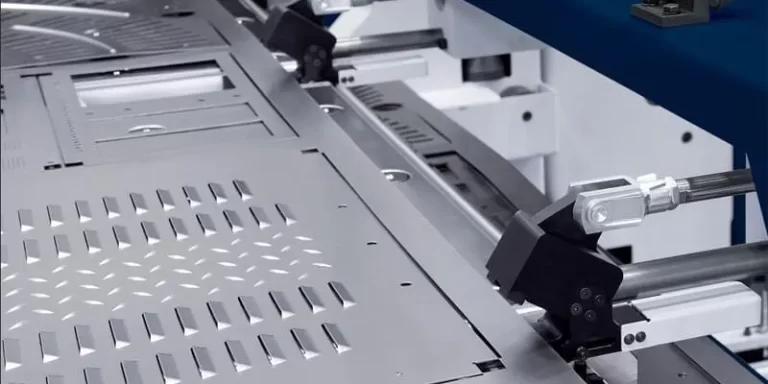

1. Overview of the 7T6395 Track Roller

The 7T6395 Track Roller is designed to facilitate smooth movement and reduce wear on tracks. It is commonly used in various heavy equipment applications.

Key Features

- Durable material designed for heavy loads.

- Enhanced performance in rugged conditions.

- Compatibility with multiple types of heavy machinery.

2. Installation Steps

Tools Required

- Socket set

- Torque wrench

- Hydraulic jack

- Safety gear (gloves, goggles)

Step-by-Step Installation Process

- Preparation

- Ensure the machine is on a stable surface and turn off the engine. Engage the parking brake for safety.

- Lift the Machine

- Use a hydraulic jack to lift the machine safely and secure it with jack stands.

- Remove the Old Track Roller

- Utilize a socket set to unfasten and remove the existing track roller from its mounting position.

- Inspect the Mounting Area

- Clean the area around the mounting point and check for any debris or damage that may need addressing.

- Install the New Track Roller

- Position the 7T6395 Track Roller in place. Secure it with bolts and tighten them using a torque wrench to the manufacturer’s specified torque setting.

- Lower the Machine

- Carefully remove the jack stands and lower the machine back to the ground.

- Test Operation

- Start the machinery and run it briefly to ensure that the new track roller operates smoothly.

3. Maintenance Tips

Routine Maintenance

- Regular Inspections: Check the track roller for any signs of wear, damage, or misalignment.

- Lubrication: Ensure that the roller bearings are adequately lubricated to minimize friction and wear.

- Track Tension Monitoring: Regularly assess the track tension to ensure it is within the manufacturer’s specifications.

- Debris Removal: Keep the area around the track roller clean to prevent any blockages or damage.

Signs of Wear

- Unusual noises during operation.

- Visible cracks or deterioration on the roller.

- Uneven wear on the tracks.

4. Troubleshooting Common Issues

| Issue | Possible Causes | Solutions |

|---|---|---|

| Excessive Noise | Worn bearings or misalignment | Inspect for wear and replace if necessary |

| Track Slippage | Improper tension or damaged roller | Adjust the track tension and check the roller |

| Uneven Wear on Tracks | Misalignment or debris obstruction | Realign tracks and clear any debris |

| Vibration during Operation | Worn components | Perform a thorough inspection and replace if needed |

5. Conclusion

The 7T6395 Track Roller is crucial for the performance of tracked heavy machinery. By following this step-by-step guide for installation, maintenance, and troubleshooting, you can ensure the longevity and efficiency of your equipment. If you have any further questions or need additional assistance, feel free to ask!