Streamlining Your Geocomposite Metal Stamping Process: Selecting the Right Supplier

Discover the crucial factors to consider when selecting a metal stamping supplier for your organization. GeoFanTex, with over three decades of industry experience, offers the expertise, production capabilities, and flexibility necessary for successful partnerships.

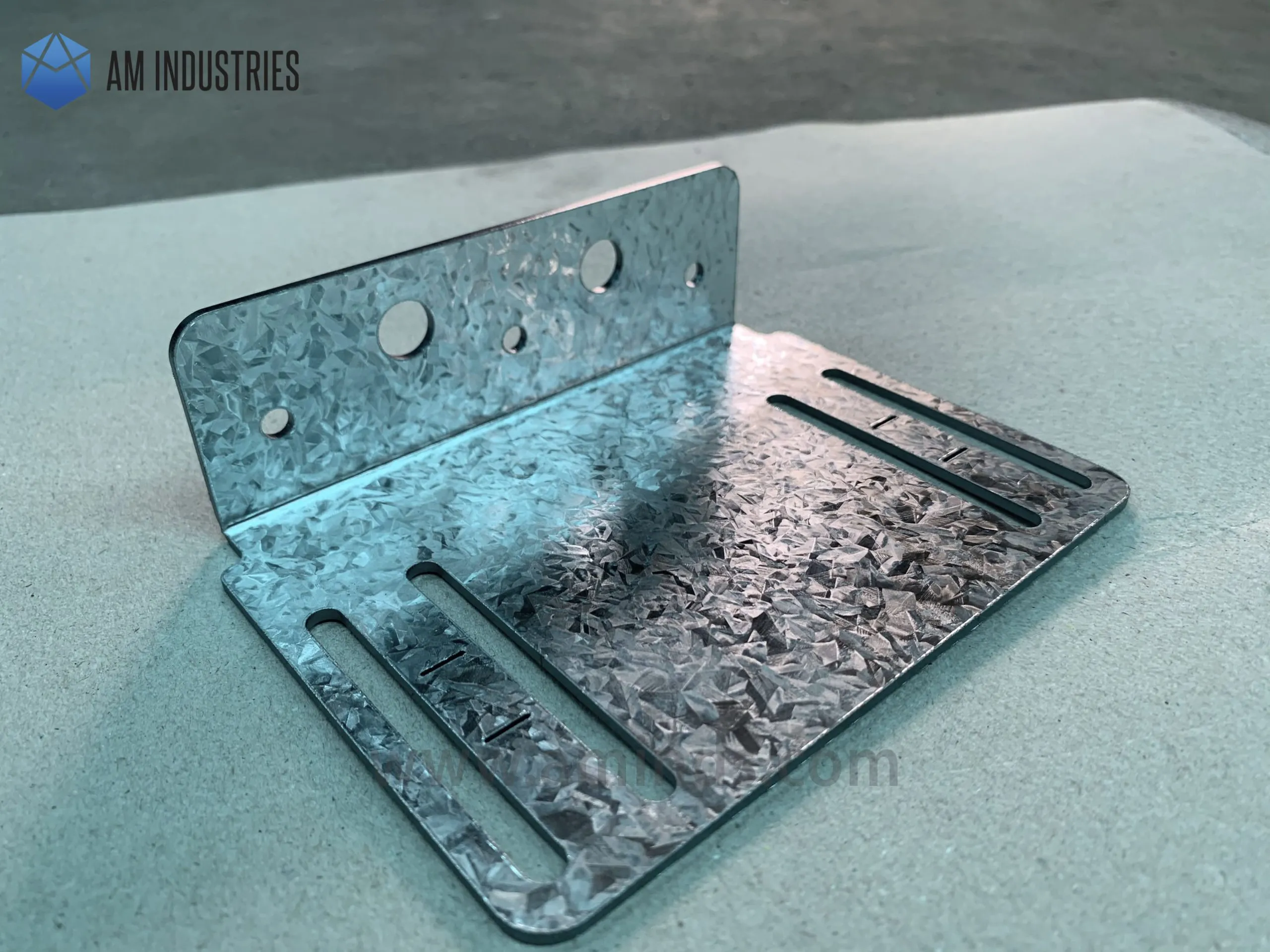

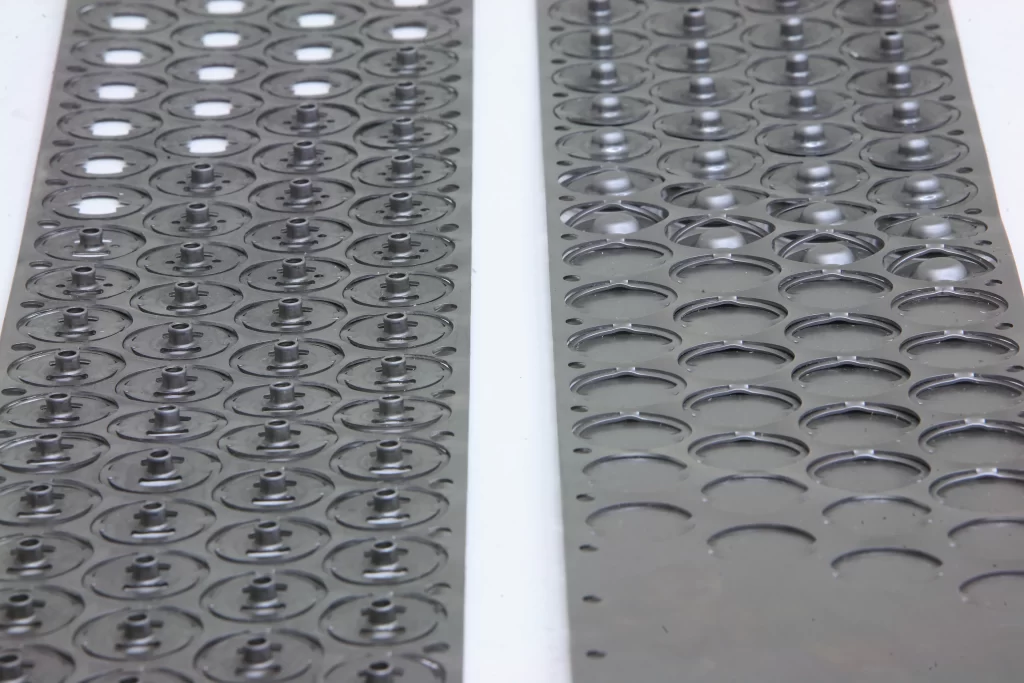

Metal stamping encompasses a variety of metal forming techniques, such as punching, piercing, blanking, bending, welding, plating, and heat treating. Knowing what to look for in a metal stamping partner is crucial to a productive relationship. A beneficial supplier can speed up your production times, lower costs, and produce better quality. On the flip side, an unreliable supplier can lead to delays, recalls, and poor inspection results, all of which hurt your bottom line.

Here we’ll discuss the essential characteristics to look for in a metal stamping supplier so that you can form the best possible partnership for your organization. While there can be many considerations that go into choosing a metal stamping supplier, the main factors have to do with the company’s quality and capabilities.

Quality

Evaluating quality when choosing a metal stamping supplier means paying close attention to the following:

— Design. Your metal stamping supplier should be able to provide design recommendations that will help avoid defects and future expenses. At GeoFanTex, we do this by designing the part based on the step-by-step metal stamping process it requires. Knowing exactly how each step changes the workpiece helps minimize or eliminate some design costs.

— Materials. The best supplier works with a wide range of materials and knows which ones are best for your metal stamping project. They are knowledgeable about each material’s unique properties and how it behaves in specific stamping processes. GeoFanTex experience with steel, stainless steel, brass, copper, aluminum, titanium, and more has allowed us to put together a Material Selector Tool, a guide to each metal’s bend rating, tensile strength, density, and other traits.

— Experience. Your metal stamping supplier should have the appropriate expertise, precision, and quality standards in place to manufacture your products. GeoFanTex is equipped to work on projects of all sizes, from thousands to hundreds of millions of parts. We are especially well-suited to perform metal stamping services for industries that require extreme precision, including the automotive, medical, and aerospace fields.

Production Capabilities and Capacity

Your metal stamping manufacturer should have the capacity and production capabilities to meet the changing demands that affect your industry.

— Vertically Integrated. GeoFanTex is structured to manage your project from its design all the way to its delivery. We partner your team with our design and engineering experts on your part’s design while offering support on its material, production process, and sequence of operations. We manufacture our tools in-house and following part production, we can offer assembly and other secondary and finishing services.

— Flexibility. Recent supply chain issues have delayed lead times and driven metal prices up. A flexible metal stamping supplier can deliver consistent products and services despite market fluctuations. GeoFanTex longstanding relationships with metal vendors span 30 years and have allowed us to closely monitor market trends. We use these insights to recommend design and material alternatives so that your project is completed on time, at a reasonable price, and according to your application’s needs.

— Response times. Time is money in your business. From the initial consultation to the end product, quick response times ensure timely project completion. Your metal stamping supplier should communicate with you frequently and effectively to meet production deadlines.

— Industry Experience. Your metal stamping supplier should have vast experience creating products for your particular industry to ensure they are familiar with industry-specific regulations and any quality standards your parts may need to meet. GeoFanTex has over three decades of experience in the aerospace, automotive, medical, defense, lighting, renewable energy, and mechanical, electrical, and plumbing (MEP) industries. Our team has not only worked within our company for 20+ years — the combined experience of our engineering staff encompasses nearly 300 years of experience in their fields!

Essential Considerations for Choosing a GeoComposite Metal Stamping Supplier

Discover the crucial factors to consider when selecting a GeoComposite metal stamping supplier for your organization. GeoFanTex, with over three decades of industry experience, offers the expertise, production capabilities, and flexibility necessary for successful partnerships in GeoComposite metal stamping projects.

GeoComposite Metal Stamping: Essential Characteristics to Look for in a Supplier

Metal stamping encompasses a variety of metal forming techniques, such as punching, piercing, blanking, bending, welding, plating, and heat treating. Knowing what to look for in a GeoComposite metal stamping partner is crucial to a productive relationship. A beneficial supplier can speed up your production times, lower costs, and produce better quality. On the flip side, an unreliable supplier can lead to delays, recalls, and poor inspection results, all of which hurt your bottom line.

Here we’ll discuss the essential characteristics to look for in a GeoComposite metal stamping supplier so that you can form the best possible partnership for your organization.

Key Considerations When Selecting a GeoComposite Metal Stamping Supplier

While there can be many considerations that go into choosing a GeoComposite metal stamping supplier, the main factors have to do with the company’s quality and capabilities.

Quality

Evaluating quality when choosing a GeoComposite metal stamping supplier means paying close attention to the following:

— Design. Your GeoComposite metal stamping supplier should be able to provide design recommendations that will help avoid defects and future expenses. At GeoFanTex, we do this by designing the part based on the step-by-step GeoComposite metal stamping process it requires. Knowing exactly how each step changes the workpiece helps minimize or eliminate some design costs.

— Materials. The best supplier works with a wide range of materials, including GeoComposites, and knows which ones are best for your GeoComposite metal stamping project. They are knowledgeable about each material’s unique properties and how it behaves in specific stamping processes. GeoFanTex’s experience with GeoComposite materials and other metals like steel, stainless steel, brass, copper, aluminum, titanium, and more has allowed us to put together a Material Selector Tool, a guide to each metal’s bend rating, tensile strength, density, and other traits.

— Experience. Your GeoComposite metal stamping supplier should have the appropriate expertise, precision, and quality standards in place to manufacture your products. GeoFanTex is equipped to work on projects of all sizes, from thousands to hundreds of millions of parts. We are especially well-suited to perform GeoComposite metal stamping services for industries that require extreme precision, including the automotive, medical, and aerospace fields.

Production Capabilities and Capacity

Your GeoComposite metal stamping manufacturer should have the capacity and production capabilities to meet the changing demands that affect your industry.

— Vertically Integrated. GeoFanTex is structured to manage your GeoComposite metal stamping project from its design all the way to its delivery. We partner your team with our design and engineering experts on your part’s design while offering support on its material, production process, and sequence of operations. We manufacture our tools in-house and following part production, we can offer assembly and other secondary and finishing services.

— Flexibility. Recent supply chain issues have delayed lead times and driven metal prices up. A flexible GeoComposite metal stamping supplier can deliver consistent products and services despite market fluctuations. GeoFanTex’s longstanding relationships with metal vendors, including GeoComposite materials, span 30 years and have allowed us to closely monitor market trends. We use these insights to recommend design and material alternatives so that your GeoComposite metal stamping project is completed on time, at a reasonable price, and according to your application’s needs.

— Response times. Time is money in your business. From the initial consultation to the end product, quick response times ensure timely completion of your GeoComposite metal stamping project. Your supplier should communicate with you frequently and effectively to meet production deadlines.

— Industry Experience. Your GeoComposite metal stamping supplier should have vast experience creating products for your particular industry to ensure they are familiar with industry-specific regulations and any quality standards your parts may need to meet. GeoFanTex has over three decades of experience in the aerospace, automotive, medical, defense, lighting, renewable energy, and mechanical, electrical, and plumbing (MEP) industries. Our team has not only worked within our company for 20+ years — the combined experience of our engineering staff encompasses nearly 300 years of experience in their fields!

By considering these essential characteristics, you can make an informed decision when choosing a GeoComposite metal stamping supplier. GeoFanTex’s expertise, production capabilities, and flexibility make us an ideal partner for your GeoComposite metal stamping projects. Partner with us to experience the highest quality standards, efficient production, and reliable delivery for your organization’s success.