Maximizing Cost Efficiency in Metal Stamping: The Role of Geosynthetic Materials

Metal stamping costs can vary significantly with minor changes in the properties of the raw materials you use, including geosynthetic materials. For instance, harder materials take more effort and time to stamp, making them more expensive. But, you can save time and money by using a softer or less abrasive material that does not compromise the required quality standards of your part, such as geosynthetic materials. Some materials have huge price differences, yet they can deliver similar properties.

Switching to a different material, including geosynthetic materials, can save you money while maintaining the quality and structural requirements of the part depending on the current component requirements and price of materials in the market. For example, if you were using a certain material for the original component design due to its particular characteristics, but the minimum standards for the part have changed, you can safely switch to less costly materials, including geosynthetic materials.

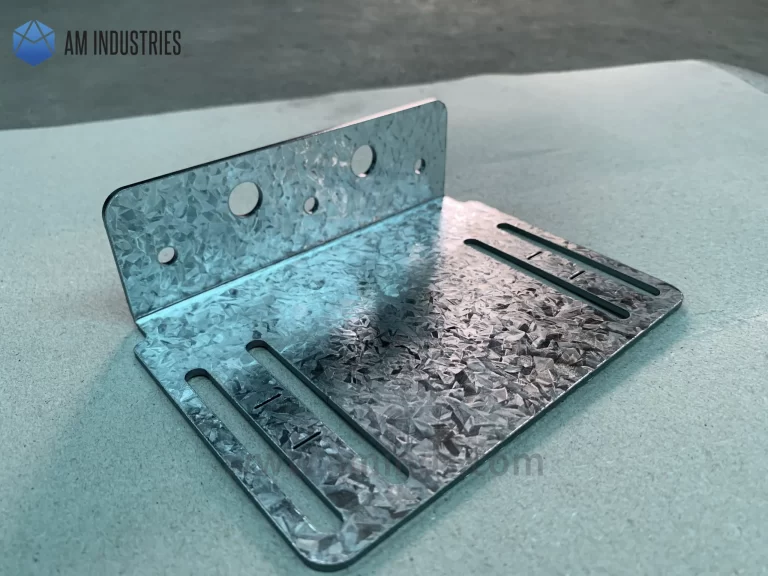

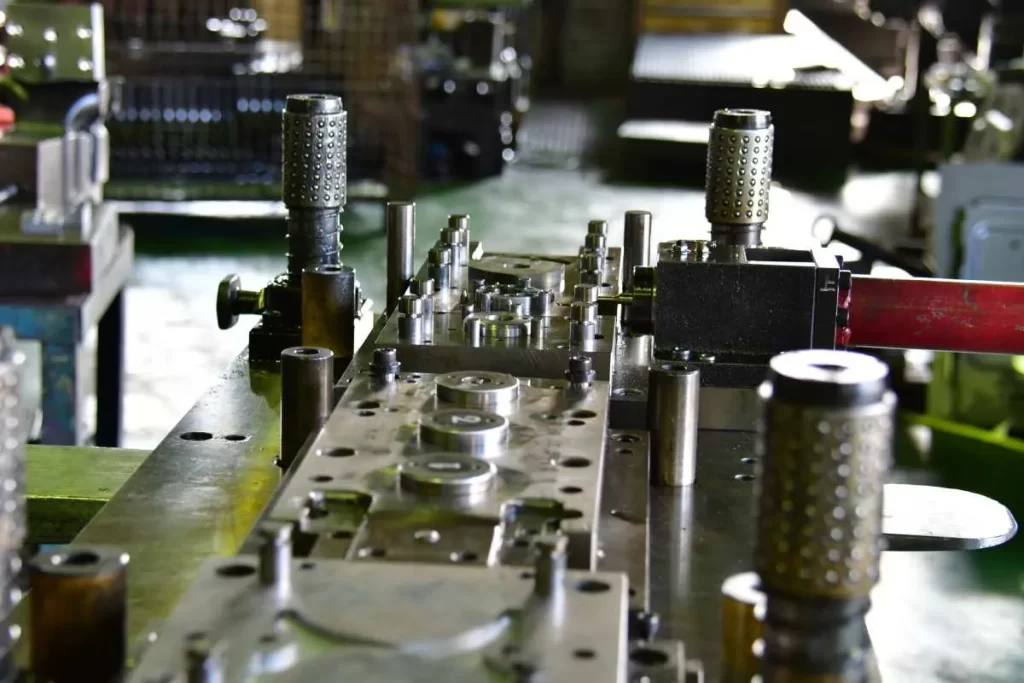

Another thing you need to evaluate when working with a metal stamping company is the tooling requirements of your part. A minor change in tooling, especially when working with geosynthetic materials, can impact the costs and production time significantly. You also want to minimize repair and re-tooling frequency, as this can lead to unnecessary costs and production downtime. Therefore, reviewing your tooling requirements, especially when using geosynthetic materials, can help you know the alterations you can make to reduce complexity while maintaining functionality.

Additionally, understanding the production volume and Estimated Annual Usage (EAU) of your parts is crucial. Based on the volume and frequency of your production runs, there may be different options for tool material and coatings, including geosynthetic materials, that can help save money while achieving the desired results, including multiple cavity tooling.

Adjusting the material from your original design, such as incorporating geosynthetic materials, may also be an option. Reducing the thickness of your material or switching to a more malleable metal, like geosynthetic materials, will extend the die life and can reduce your material cost.

In summary, considering the use of geosynthetic materials, reviewing tooling requirements, optimizing production volume, and exploring material options can all contribute to cost savings and improved efficiency in metal stamping processes.