Seepex Pump Manual: Everything You Need to Know

When it comes to industrial pumping solutions, Seepex pumps are renowned for their efficiency and reliability. Understanding how to operate and maintain these pumps is crucial for optimal performance. This article will guide you through the essential aspects of the Seepex pump manual, ensuring you have all the information you need at your fingertips.

Overview of Seepex Pumps

Seepex pumps are progressive cavity pumps designed for a variety of applications, including wastewater treatment, food processing, and chemical handling. Their unique design allows for the smooth transfer of viscous and shear-sensitive fluids. With a focus on durability and low maintenance, these pumps are a solid choice for many industries.

Key Components of the Seepex Pump

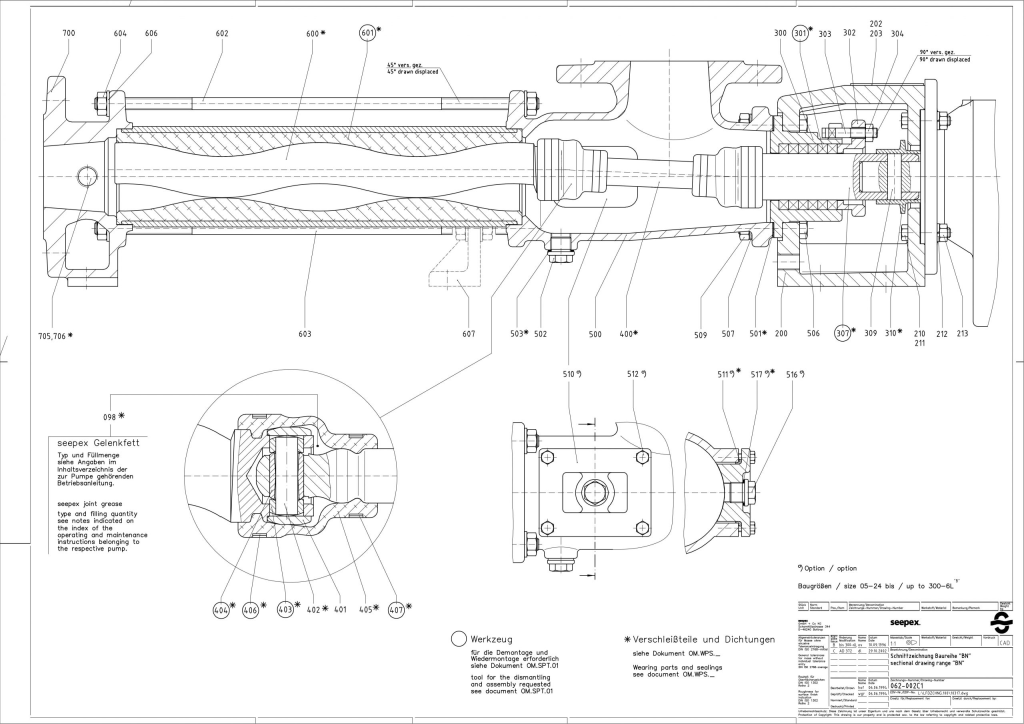

To fully understand the Seepex pump manual, it is essential to familiarize yourself with its key components:

- Stator: The elastic component that works in conjunction with the rotor to create a pumping action.

- Rotor: The helical screw that moves the fluid through the pump.

- Drive Unit: Provides the necessary power for the rotor to function.

- Discharge Port: The outlet where the fluid exits the pump.

Operating the Seepex Pump

The Seepex pump manual provides detailed instructions on how to operate the pump efficiently. Here are some fundamental operating procedures:

- Start-Up Procedure:

- Ensure that all connections are secure.

- Check the fluid levels before starting the pump.

- Gradually increase the pump speed to avoid sudden pressure changes.

- Monitoring Performance:

- Regularly check the pressure readings.

- Listen for unusual noises that may indicate a problem.

- Keep an eye on the temperature to prevent overheating.

- Shut-Down Procedure:

- Gradually decrease the pump speed.

- Stop the power supply once the pump has completely stopped.

- Perform a quick inspection for any potential issues.

Maintenance Tips

Regular maintenance is vital for extending the lifespan of your Seepex pump. The manual outlines several maintenance tasks that should be performed periodically:

- Lubrication: Ensure that all moving parts are adequately lubricated to reduce friction.

- Seal Inspection: Regularly check the seals for wear and tear to prevent leaks.

- Component Replacement: Follow the manual’s guidelines on when to replace worn-out components to maintain efficiency.

Troubleshooting Common Issues

Even with proper operation and maintenance, issues may arise. The Seepex pump manual includes a troubleshooting section that covers common challenges:

- Low Flow Rates: Check for blockages in the suction line or a damaged rotor.

- Excessive Noise: Inspect for loose components or insufficient lubrication.

- Overheating: Ensure that the pump is not running dry and that cooling systems are functioning properly.

Conclusion

The Seepex pump manual is an invaluable resource for anyone involved in the operation and maintenance of Seepex pumps. By understanding the key components, following operational guidelines, and performing regular maintenance, you can ensure the longevity and efficiency of your pumping systems. Always refer to the manual for specific instructions tailored to your pump model, and stay informed about best practices in pump management.